what are the three basic areas of a machine that require safeguarding

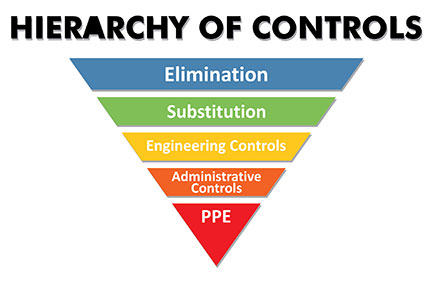

The basic steps to prevent accidents are- Eliminate the hazard from the machine method material structure etc. The point where work is performed on the material such as cutting shaping boring or forming of stock.

Ctci Group Msw Exam Pollution Prevention Workplace Safety

Mechanical hazards typically involve dangerous moving parts in the following three basic areas.

. Machine Safeguarding page 2 of 4 Where Mechanical Hazards Occur Dangerous moving parts in the following three basic areas require safeguarding. That point where work is performed on the material such as cutting shaping boring or forming of stock. These include moving belts arms.

Moving parts which are part of the machine or bigger system. There are several mechanical motions that pose risks to workers. The point of operation.

Dangerous moving parts in three basic areas require machine safeguarding. Dangerous moving parts in three basic areas require safeguarding. The point of operation is the area on a machine where the work is performed.

That point where work is performed on the material such as cutting shaping boring or forming of stock. Dangerous moving parts in three basic areas require machine safeguarding. Any machine part function or.

Crushed hands and arms severed fingers blindness -- the list of possible machinery-related injuries is as long as it is horrifying. All components of the mechanical system which transmit energy to the part of the machine performing the work. Rotating reciprocating and transverse.

Power transmission apparatus which feeds energy to machines. What are the three basic areas of a machine that require safeguarding. Safeguards are essential for protecting workers from needless and preventable.

It may stop the machine if a hand or any part of the body is inadvertently placed in the danger area. Despite all machines having the same basic components their safeguarding needs widely differ due to varying physical characteristics and operator involvement. These components include flywheels.

All components of the mechanical. There are many ways to safeguard machinery. Three basic areas require safeguarding.

What are the three types of equipmentmachine motions that present hazards to the worker. All components of the mechanical system which transmit energy to the part of the machine performing the work. Cutting Shaping Boring Forming.

All components of the mechanical system which transmit energy to the part of the machine performing the work. Point of Operation Power Transmission Apparatus Other Moving Parts Question 2. All machines consist of three fundamental areas the point of operation the power.

Other danger areas Point of operation Power transmission apparatus 3. What are the three basic areas of a machine that require safeguarding. OSHA states that mechanical hazards are most likely to occur in three major areas.

That point where work is performed on the material such as cutting shaping boring or forming of stock. The point of operation. Control the hazard by enclosing or guarding at its source.

Train personnel to know that hazard and follow the safe job method to avoid. The point of operation from where all the work is performed. These components include flywheels.

What are the three types of in-running nip points. The following pages address the general requirements for machinery set forth by. Three basic area require machine safeguarding.

Dangerous moving parts in three basic areas require safeguarding. All components of the mechanical system which transmit energy to the part of the machine. The point of operation.

That point where work is performed on the material such as cutting shaping boring or forming of stock. Parts rotating in o_____ direction. Three basic area require machine safeguarding.

Basics of Machine Safeguarding. The point of operation. Basics of Machine Safeguarding.

Also know what are the most. Dangerous moving parts in three basic areas require safeguarding. Dangerous moving parts in three basic areas require safeguarding.

IPsec TLS or any other protocol require interaction of software. Any machine part function or process which may cause injury must be safeguarded. All machines consist of three fundamental areas.

What are the three basic areas of a machine that require safeguarding. The point is that location where an operation is performed on stock or material. The point where work is performed on the material such as cutting shaping boring or forming of stock.

There are three permissible exceptions to the basic rule on patentability. The point of operation. The point of operation that point where work is performed on the material.

There seem to be as many hazards created by moving machine parts as there are types of machines. Methods of Machine Safeguarding. Power transmission apparatus which feeds.

Dangerous moving parts in three basic areas require safeguarding. Dangerous moving parts in three basic areas require safeguarding. R_____ R_____ T_____ 4.

Three basic area require machine safeguarding. Lee needs to move a large. Dangerous moving parts in three basic areas require safeguarding.

All components of the mechanical system which transmit energy to the part of the machine performing the work. The point is that location where an operation is performed on stock or material. All components of the mechanical system which transmit energy to the part of the machine performing the work.

Dangerous moving parts in three basic areas require safeguarding. The point of operation. The type of operation the size or shape of stock the method of handling the physical.

The types of waste include processes activities products or services that require time money or skills but do not create value for the customer. The point of operation. The point of operation the power transmission device and the operating controls.

The point of operation. The point of operation from where all the work is performed. Flying chips and sparks created by a machine.

Oshacademy Course 154 Machine Safeguarding Basic Module 1

Concepts Techniques Of Machine Safeguarding Chapter 2

Oshacademy Course 154 Machine Safeguarding Basic Module 1

Oshacademy Course 154 Machine Safeguarding Basic Module 1

Three Steps To Preventing Machine Injuries Ul

Oshacademy Course 154 Machine Safeguarding Basic Module 1

The Distribution Of Ai Enabled Research Is Seen Across Three Classes Of Adopters Advanced Trading Competitive Data Scientist Digital Transformation Investing

Basics Of Machine Guarding My Loss Control Services

Basics Of Machine Guarding My Loss Control Services

Ctci Group Msw Exam Pollution Prevention Workplace Safety

Cloudflare Completes Acquisition Of Area 1 Security In 2022 Security Network Security Areas

What Is Machine Guarding And Why Is It Important Safetycompany Com

Oshacademy Course 154 Machine Safeguarding Basic Module 1

Oshacademy Course 154 Machine Safeguarding Basic Module 1

Essential Updates To Machine Safety Standards Ul

Abb Launched Irb 6790 Foundry Prime Robot Which Is Used At High Pressure Water Jet Cl Life Cycle Management Information And Communications Technology Marketing